Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

When you’re ready to upgrade your garage, it’s tempting to focus on layout or fancy storage systems. But if your cabinets can’t handle the environment—or worse, fall apart after a few seasons—you’re back to square one. Choosing the right material for garage cabinets is more than just a design decision. It’s about longevity, weight capacity, moisture resistance, and ease of maintenance.

I found this out the hard way. When I began my garage overhaul, I thought cabinets were just cabinets—until I had to pick the material. MDF looked smooth, plywood sounded sturdy, and melamine seemed sleek. After lots of hands-on work (and a few mistakes), I discovered there’s no one-size-fits-all answer—but there’s definitely a best material for your specific needs.

Unlike your kitchen or home office, your garage goes through serious environmental stress. It’s common for garages to face fluctuating temperatures, high humidity, or even direct exposure to water and dust. All of this affects how cabinet materials perform over time.

For example, I quickly learned that MDF swells like a sponge in humid conditions unless it’s properly sealed. Even some so-called “garage-rated” particle boards couldn’t hold up under seasonal weather swings. Meanwhile, materials like exterior-grade plywood and metal handled moisture far better, especially when sealed or coated properly.

So, before picking any cabinet material, you need to ask:

How much moisture will the cabinets face?

Will you store heavy tools or light gear?

Is appearance or function more important?

Only then can you pick a material that won’t warp, swell, or buckle under pressure.

Aluminum: Strength, Weight & Longevity

Aluminum is the star of the show for premium garage cabinetry. It’s lightweight, corrosion-resistant, and incredibly strong. Brands like Moduline swear by aluminum for both residential and professional garages—and for good reason.

Pros:

Immune to rust and moisture damage

Lightweight but very durable

Easy to clean and maintain

Gives a sleek, modern industrial look

Cons:

Price tag—this isn’t the budget option

Limited DIY flexibility (usually pre-fab only)

If you want zero maintenance and plan to stay in your home for years, aluminum is a solid investment. That said, I opted out because of the price—especially since I needed over 20 linear feet of cabinets.

Plywood (Birch Exterior): Strength Under Load

Plywood, especially exterior-grade birch, was a lifesaver in my garage build. It’s made of cross-laminated wood layers that resist warping and support a lot of weight. I used this for my cabinet boxes and shelves, and it’s held up incredibly well—even under heavy paint cans, power tools, and car parts.

What I loved:

Holds screws like a champ

Resists moisture better than MDF

Strong, stable, and long-lasting

What I didn’t love:

Costs more than MDF

Edges look rough unless sanded and sealed

Can splinter if not cut cleanly

I wouldn’t use anything else for structural areas—plywood is worth every penny.

MDF: Affordable Painted Finish

Medium-Density Fiberboard is great for smooth, clean finishes. It’s made from wood fibers and resin, offering flat, knot-free surfaces—ideal if you plan to paint.

I used MDF for my cabinet doors and it worked beautifully, especially when color-matching to the rest of the garage.

Pros:

Very affordable

Smooth, consistent surface for painting

No warping or knots

Cons:

Heavy—really heavy

Weak against water and humidity

Chips and scratches easily

If you’re going to paint and keep things dry, MDF is a decent choice—but use it wisely. In my case, it was perfect for painted fronts but not for anything structural.

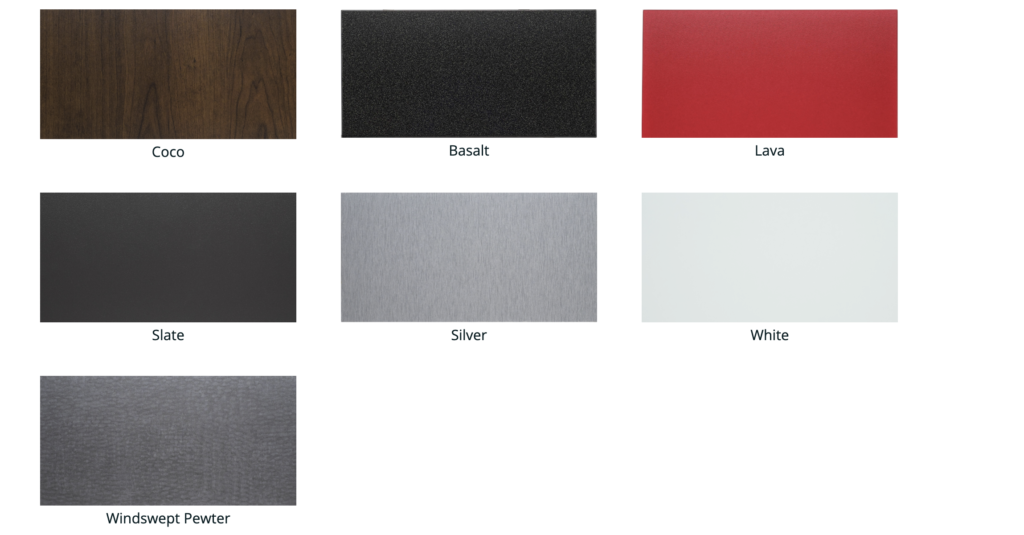

Melamine: Easy-to-Clean Modern Look

Melamine caught my eye for its modern look and wipe-clean surface. It’s made of a resin-coated board (usually particleboard or MDF) with a paper overlay, offering a finished look without any extra work.

In my build, I noticed:

Super easy to clean

Lots of finish and color options

Good moisture and heat resistance

But also:

Chips like crazy when cutting

Requires precision for screw placement

Can crack if mishandled

It’s a great choice for shelf surfaces where aesthetics matter. I used it on horizontal surfaces for that clean, polished look—and I’m glad I did.

Particle Board: Budget Option with Limitations

Lastly, I tested particle board—the budget hero. Made from compressed wood chips and glue, it’s cheaper and lighter than MDF or plywood.

My thoughts:

It’s very affordable

Light and easy to handle

Accepts paint and laminate well

But it failed me in:

Load-bearing tasks

Humid conditions (swells quickly)

Holding screws securely

I only used particle board for small, dry-storage areas. Anywhere else, it just couldn’t perform reliably.

There’s no universal “best” material—it really depends on what you’re storing, your garage environment, and your skill level. Ask yourself:

Will these cabinets support heavy tools or just holiday decor?

Do you live in a humid or dry climate?

Are you painting the cabinets or using a pre-finished surface?

Do you plan to DIY or buy pre-assembled units?

From my experience, matching the material to the specific cabinet role (frame vs door vs shelf) made all the difference in durability and usability.

One strategy I discovered through trial and error: mix and match materials. You don’t need to use one single type of board for your whole build.

In my case:

I used exterior-grade birch plywood for the cabinet boxes—structurally solid and reliable under weight.

For door fronts, I went with MDF—easy to paint and keeps a sleek look.

Shelving got the melamine treatment—simple to clean and resistant to most garage messes.

This hybrid approach gave me the best of all worlds: strength, aesthetics, and affordability. My tip: Don’t waste top-dollar materials on areas no one sees or touches—use them where it counts.

Here’s a quick recap of what I actually used, and how it worked out:

MDF: Great for painted fronts. Heavy and not ideal for wet zones.

Birch Plywood: Rock-solid base structure. Held up under heavy items without warping.

Melamine: Perfect for modern-looking, wipe-clean shelves. Fragile edges needed caution.

Particle Board: Only useful in very light-duty spots. Budget-friendly, but risky elsewhere.

This blend worked beautifully, but not without effort. I had to pre-drill carefully, use edge banding on plywood, and support MDF doors properly. Still, the result? A garage that looks pro-built—and actually functions like it, too.

So, what’s the best material for garage cabinets? The honest answer: it depends on how you use your space. Every material has strengths and drawbacks—but with a bit of planning, you can build a system that looks great, lasts for years, and works exactly the way you need.

My recommendation? Use plywood for strength, MDF for a smooth painted finish, and melamine where clean-up and aesthetics matter. Skip particle board unless it’s a temporary or lightweight solution. And if your budget allows, aluminum is an unbeatable, maintenance-free choice.